A look behind the laboratory doors of dental technology

Antje Wilmerstadt and her team of dental technicians introduced us to their exciting fields of work, technologies and variety of materials used for modern dental restorations.

Photos: Rebecca Höpfer und Dennis Zhang

Practical insight into the craft of dental technology with illustrative examples (Bild 1 von 7) » Vorwärts

Practical insight into the craft of dental technology with illustrative examples (Bild 1 von 7) » Vorwärts « ZurückPractical insight into the craft of dental technology with illustrative examples (Bild 2 von 7) » Vorwärts

« ZurückPractical insight into the craft of dental technology with illustrative examples (Bild 2 von 7) » Vorwärts « ZurückPlaster models of an upper and lower jaw with dentures mounted in an articulator (Bild 3 von 7) » Vorwärts

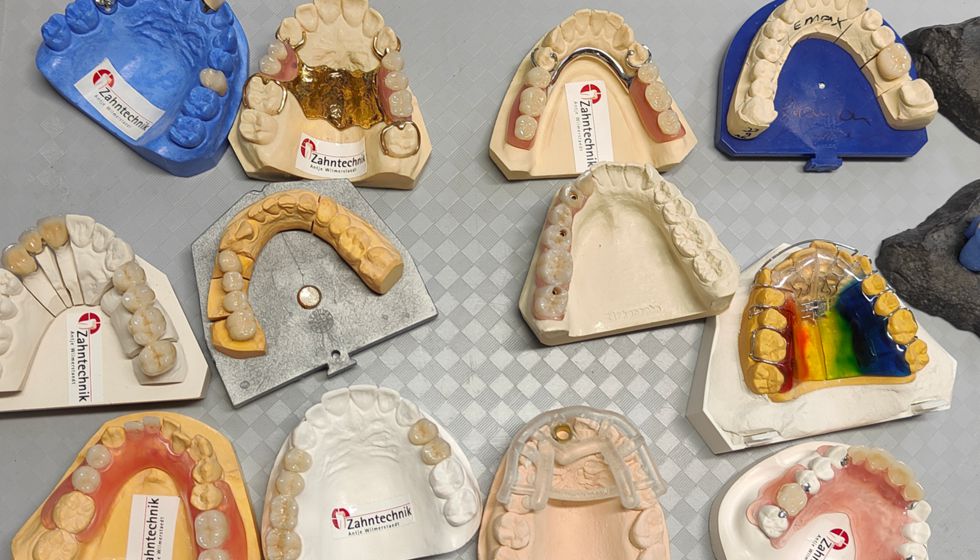

« ZurückPlaster models of an upper and lower jaw with dentures mounted in an articulator (Bild 3 von 7) » Vorwärts « ZurückExamples of various types of patient-specific dentures adapted to the plaster cast (Bild 4 von 7) » Vorwärts

« ZurückExamples of various types of patient-specific dentures adapted to the plaster cast (Bild 4 von 7) » Vorwärts « ZurückOptical and tactile dental scanner that detects the position and alignment of the dental model and implants (Bild 5 von 7) » Vorwärts

« ZurückOptical and tactile dental scanner that detects the position and alignment of the dental model and implants (Bild 5 von 7) » Vorwärts « ZurückOptical and tactile dental scanner that detects the position and alignment of the dental model and implants (Bild 6 von 7) » Vorwärts

« ZurückOptical and tactile dental scanner that detects the position and alignment of the dental model and implants (Bild 6 von 7) » Vorwärts « ZurückCAD dental software for modeling and planning the dental prosthesis (Bild 7 von 7)

« ZurückCAD dental software for modeling and planning the dental prosthesis (Bild 7 von 7)

Excursion to the dental lab Wilmerstaedt

As part of the Biomedical Materials course, we students of the Biomechanical Engineering master's program were offered the chance to visit the dental laboratory of dental technician Antje Wilmerstaedt.

Dental technology deals with the production of all types of dental prostheses, such as dental crowns, bridges and dentures, but also with the production of splints and braces. After a brief introductory presentation on the field, we were given a guided tour of the laboratory, where we were shown the individual work steps required to produce a modern dental prosthesis.

The starting point is always an impression of the patient's dentition, which the dentist delivers to the laboratory. This is used to create a plaster model, which is used for all further processes in order to produce the dentures with a precise, highly individualized fit. With the help of an articulator, which simulates the position and movement of the temporomandibular joint, it is ensured that the upper and lower jaw models fit together exactly.

Dentures can basically be fabricated in two different ways: either by creating a negative and pouring in an acrylic or metal, or by milling the denture from a blank based on digital CAD scans.

In both cases, the color of the tooth is adapted to the patient by applying a ceramic to make the replacement appear as natural as possible. Fixing the prosthesis in the mouth can be done in various ways. For example, in the case of a bridge, the teeth to the left and right of the gap are ground down and the prosthesis is fitted. Unlike an implant, where the denture is permanently screwed into the jaw with metal pins and grows together with the bone, a bridge can be removed again. Denture fabrication offers a wide range of fabrication options. These are necessary to find the ideal solution of a restoration based on the complex tooth anatomy and the individual needs of each patient.

As prospective medical engineers, the dental industry offers career prospects in the development of innovative, dental products. Particularly impressive is the aspect of the right choice of materials from the wide variety of dental materials that have to meet the demanding application in the mouth in the long term. In addition, the integration of modern equipment technology and software, such as milling machines, CAD/CAM systems with 3D scanner technologies or 3D printers, showed us further fields of work and research for our professional future.

We would like to sincerely thank Antje Wilmerstaedt and her dental technology team for the interesting gain in knowledge, the practical, exciting insights behind her laboratory doors and the very friendly exchange.

Author: Rebecca Höpfer